Difference between revisions of "Eurodyne Tables"

| (40 intermediate revisions by 4 users not shown) | |||

| Line 3: | Line 3: | ||

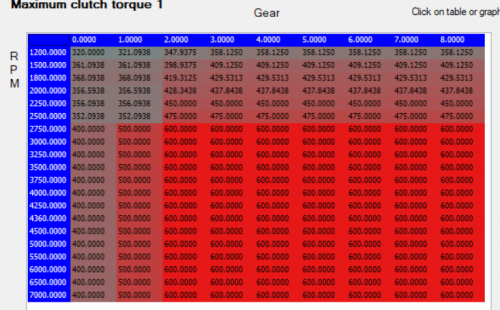

=== Maximum Clutch Torque === | === Maximum Clutch Torque === | ||

The Maximum Clutch Torque tables are used to define the maximum available torque based on RPM and gear. The two tables represent MANUAL and DSG transmissions. | The Maximum Clutch Torque tables are used to define the maximum available torque based on RPM and gear. The two tables represent MANUAL and DSG transmissions. | ||

| − | The ECU will look at the current Driver requested torque percentage (input from the pedal), along with the current RPM to arrive at the target torque value | + | The ECU will look at the current Driver requested torque percentage (input from the pedal), along with the current RPM to arrive at the target torque value. |

| + | |||

| + | The Max torque tables can be used to limit torque delivery in certain gears. | ||

| + | |||

| + | [[File:boss_maxclutchtorque.png|500px]] | ||

== Fueling == | == Fueling == | ||

=== Basic Lambda vs Airmass DI === | === Basic Lambda vs Airmass DI === | ||

This table is the ''part throttle'' fueling map. The ECU will target the entered lambda values during part throttle (not pedal position). At full throttle, the ECU will switch to the "Full Load Lambda" fueling table. <br> | This table is the ''part throttle'' fueling map. The ECU will target the entered lambda values during part throttle (not pedal position). At full throttle, the ECU will switch to the "Full Load Lambda" fueling table. <br> | ||

| + | |||

| + | The Airmass DI tables axes are defined '''INCORRECTLY''' in Maestro. When tuning the DI tables, make your changes with the below axes in mind, but do '''not''' change the axes values in Maestro: | ||

| + | <br> | ||

| + | |||

| + | [[File:Screen Shot 2021-01-19 at 9.30.27 PM.png]] | ||

| + | |||

'''Note:''' "Full Throttle" can happen even if the accelerator pedal is not pushed completely down. | '''Note:''' "Full Throttle" can happen even if the accelerator pedal is not pushed completely down. | ||

| − | + | ||

=== Full Load Lambda === | === Full Load Lambda === | ||

This table is referenced when the ECU is in a full throttle situation. The X-Axis represents time elapsed in full load in seconds. | This table is referenced when the ECU is in a full throttle situation. The X-Axis represents time elapsed in full load in seconds. | ||

| Line 18: | Line 28: | ||

=== Minimum Lambda Target === | === Minimum Lambda Target === | ||

| − | This is the absolute lowest lambda value that the ECU will target. The ECU will | + | This is the absolute lowest lambda value that the ECU will target. The ECU will ignore any lower values in other fueling tables. |

== Boost == | == Boost == | ||

=== Maximum Turbo Pressure Ratio === | === Maximum Turbo Pressure Ratio === | ||

This table is used to define the maximum turbo boost at a given RPM range. The ECU will not attempt to overshoot this boost value. Measurements are relative boost pressure *not* absolute pressure. | This table is used to define the maximum turbo boost at a given RPM range. The ECU will not attempt to overshoot this boost value. Measurements are relative boost pressure *not* absolute pressure. | ||

| + | |||

| + | [[File:maxturbopressureratio.png|500px]] | ||

=== Map for boost pressure actuator setpoint === | === Map for boost pressure actuator setpoint === | ||

| − | More commonly known as... wastegate duty cycle. | + | More commonly known as... wastegate duty cycle. |

| + | |||

| + | ==== Factory ASW ==== | ||

| + | FIRST PASS, NEED MORE DATA TO CONFIRM: | ||

| + | |||

| + | The way the wastegate duty cycle works is based on modeled turbocharger tables that calculate the turbine intake and exhaust flow factors. It's *impossible* to tune the wgdc on an ED tune without additional logging capability. | ||

| + | |||

| + | One possible way to tune the wgdc is to measure the following 4 variables: | ||

| − | + | <pre> | |

| − | + | fac_1_put_ad - first parameter for precontrol and adaptation | |

| + | fac_2_put_ad - second parameter for precontrol and adaptation | ||

| + | fac_pow_put_ctl_opl - Open loop value of PUT control | ||

| + | fac_pow_put_ctl_rgl - Regular value for PUT control | ||

| + | </pre> | ||

| − | + | In maestro, the axes are labeled incorrectly. | |

| − | + | The X value is *actually* <code>fac_2_put_ad</code>, and the Y value is *actually* <code>fac_1_put_ad</code>. | |

| − | + | Calculating the difference between <code>fac_pow_put_ctl_opl</code> and <code>fac_pow_put_ctl_rgl</code> will tell you how far off your wgdc table is from your actual wastegate control. | |

| + | |||

| + | [[File:is20_wgdc.png|500px]] | ||

==== Boss/Big turbo version ==== | ==== Boss/Big turbo version ==== | ||

| + | |||

| + | The Boss file uses a different strategy that's much more straightforward. To maintain X Boost at Y RPM open the gate Z percentage. | ||

| + | |||

| + | [[File:boss_wgdc.png|500px]] | ||

== Timing == | == Timing == | ||

| − | + | Ignition timing is determined by two look-up tables (Ignition timing, low octane and Ignition timing, high octane) and two settings tables (Min octane for adjustable features and Max octane for adjustable features). Within the Simos18 ECU there are additional lookup tables that will impact timing that Maestro does not access. Intake Air Temperature (IAT) as recorded by the MAP sensor is one such variable that will impact your timing advance. High IATs will retard timing to reduce the likelihood of pre-ignition due to high combustion temperatures within the cylinder. The ECU will override the two Maestro timing tables to ensure engine longevity in the face of extreme environmental conditions. | |

| + | |||

| + | '''Min and Max octane for adjustable features''' | ||

| + | |||

| + | The two adjustable tables appear to represent timing for 80(low) and 100(high) octane. Setting the octane slider to some number will cause the ECU to perform a lookup against a (hidden to the user) table which defines the interpolation factor used to determine basic ignition angle. The min and max octane for adjustable features calibration settings are merely used to adjust the window that the slider will operate in. These two settings will not impact the timing interpolation. | ||

| + | |||

| + | '''Ignition timing, low and high octane''' | ||

| + | |||

| + | The tables have 3 axis: | ||

| + | |||

| + | * X axis is Air Mass per stroke | ||

| + | * Y Axis is Engine speed (RPM) | ||

| + | * Z axis (the field of cells) is ignition timing | ||

| + | |||

| + | As with any table within Maestro, the X and Y values can be modified to suit the users needs, however the Air Mass and RPM values as set on the base files should satisfy 99.99% of users and are not recommended to be modified. | ||

| + | |||

| + | '''Setting a Timing Curve''' | ||

| + | |||

| + | WARNING...DO NOT ADJUST ANY OF THE TIMING VALUES IN THE COLUMNS BELOW 1000MG/STROKE. Why? Daily driving around town from stoplight to stoplight the engine uses ignition timing fairly aggressively due to the lack of airmass (which is due to the lack of exhaust volume spinning the turbine) to power the vehicle. If you lower these values the car will feel sluggish at part throttle. If you increase these values the engine will knock. Only make changes to the last few columns of the tables. Once you get comfortable with tuning and are looking to move to more advanced manipulation (i.e bigger turbo, E85 blend timing, etc..) you may feel the need to increase or decrease values in some of the air mass columns in the 600-900 range. For larger framed/slow spooling turbos you may need to increase timing at low air mass to remove the off/on feeling. Winter gas blends often have less knock resistance that can often lead to excess low air mass/spool knock that one may seek to reduce without also reducing overall timing by adjusting the slider. Use your datalogs to make adjustments as needed. If you are consistently seeing knock in a few cylinders at a specific RPM range then adjust the timing down at that RPM and air mass area. It's best to make timing adjustments to both tables equally (or as equal as possible). If you are going to pull 1 degree of timing out at 6000 rpm in the 1299 air mass column then pull 0.375 from one and 0.75 from the other. If you feel like you need further reductions then pull more from the table that got the 0.375 reduction. | ||

| + | |||

| + | '''How much KR is too much KR?''' | ||

| + | |||

| + | This question comes up quite often. The answer is whatever you are most comfortable with. Some people don't want to see any KR. Some people say anything up to -3 degrees in 2 cylinders or less at the same time is ok. Most would agree that -4 or more is not a great idea and one should remedy that. Some cars seem more prone to KR, some have KR at specific RPM ranges that can't be removed with meth or even full E85. You might see one cylinder in particular that has more KR events than the others. Every motor is different. Use your own comfort level when setting timing. | ||

| + | |||

| + | '''~*~*~*~* Flame 'n' Bang ~*~*~*~*''' | ||

| + | |||

| + | You bang, bang, bang, bang, bang | ||

| + | |||

| + | Then flame, flame, flame | ||

| + | |||

| + | You bang, bang, bang, bang, bang | ||

| + | |||

| + | It's not my thing, so let it go | ||

| + | -Diggs | ||

= Unofficial changelog = | = Unofficial changelog = | ||

Lol | Lol | ||

Latest revision as of 17:57, 27 January 2021

Calibration tables

Limiters

Maximum Clutch Torque

The Maximum Clutch Torque tables are used to define the maximum available torque based on RPM and gear. The two tables represent MANUAL and DSG transmissions. The ECU will look at the current Driver requested torque percentage (input from the pedal), along with the current RPM to arrive at the target torque value.

The Max torque tables can be used to limit torque delivery in certain gears.

Fueling

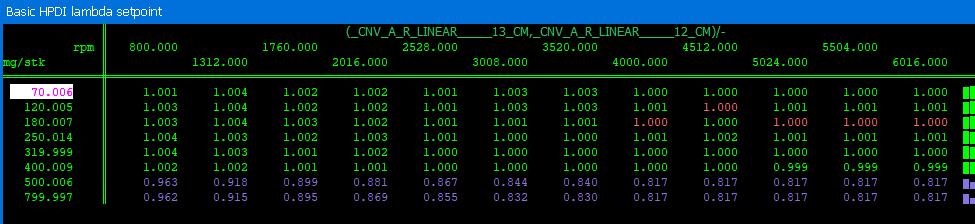

Basic Lambda vs Airmass DI

This table is the part throttle fueling map. The ECU will target the entered lambda values during part throttle (not pedal position). At full throttle, the ECU will switch to the "Full Load Lambda" fueling table.

The Airmass DI tables axes are defined INCORRECTLY in Maestro. When tuning the DI tables, make your changes with the below axes in mind, but do not change the axes values in Maestro:

Note: "Full Throttle" can happen even if the accelerator pedal is not pushed completely down.

Full Load Lambda

This table is referenced when the ECU is in a full throttle situation. The X-Axis represents time elapsed in full load in seconds.

Lambda EGT Protection

This table determines the lambda target when the ECU determines EGT (exhaust gas temperature) is too high. You may consider using targets which are not as rich if you have an aftermarket DP.

Minimum Lambda Target

This is the absolute lowest lambda value that the ECU will target. The ECU will ignore any lower values in other fueling tables.

Boost

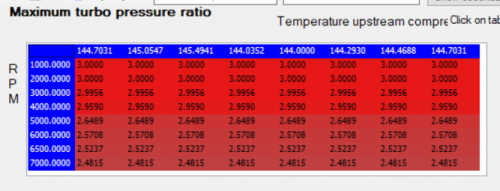

Maximum Turbo Pressure Ratio

This table is used to define the maximum turbo boost at a given RPM range. The ECU will not attempt to overshoot this boost value. Measurements are relative boost pressure *not* absolute pressure.

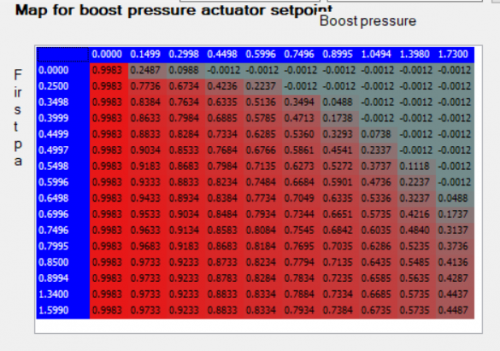

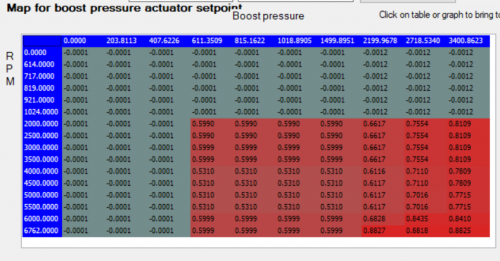

Map for boost pressure actuator setpoint

More commonly known as... wastegate duty cycle.

Factory ASW

FIRST PASS, NEED MORE DATA TO CONFIRM:

The way the wastegate duty cycle works is based on modeled turbocharger tables that calculate the turbine intake and exhaust flow factors. It's *impossible* to tune the wgdc on an ED tune without additional logging capability.

One possible way to tune the wgdc is to measure the following 4 variables:

fac_1_put_ad - first parameter for precontrol and adaptation fac_2_put_ad - second parameter for precontrol and adaptation fac_pow_put_ctl_opl - Open loop value of PUT control fac_pow_put_ctl_rgl - Regular value for PUT control

In maestro, the axes are labeled incorrectly.

The X value is *actually* fac_2_put_ad, and the Y value is *actually* fac_1_put_ad.

Calculating the difference between fac_pow_put_ctl_opl and fac_pow_put_ctl_rgl will tell you how far off your wgdc table is from your actual wastegate control.

Boss/Big turbo version

The Boss file uses a different strategy that's much more straightforward. To maintain X Boost at Y RPM open the gate Z percentage.

Timing

Ignition timing is determined by two look-up tables (Ignition timing, low octane and Ignition timing, high octane) and two settings tables (Min octane for adjustable features and Max octane for adjustable features). Within the Simos18 ECU there are additional lookup tables that will impact timing that Maestro does not access. Intake Air Temperature (IAT) as recorded by the MAP sensor is one such variable that will impact your timing advance. High IATs will retard timing to reduce the likelihood of pre-ignition due to high combustion temperatures within the cylinder. The ECU will override the two Maestro timing tables to ensure engine longevity in the face of extreme environmental conditions.

Min and Max octane for adjustable features

The two adjustable tables appear to represent timing for 80(low) and 100(high) octane. Setting the octane slider to some number will cause the ECU to perform a lookup against a (hidden to the user) table which defines the interpolation factor used to determine basic ignition angle. The min and max octane for adjustable features calibration settings are merely used to adjust the window that the slider will operate in. These two settings will not impact the timing interpolation.

Ignition timing, low and high octane

The tables have 3 axis:

- X axis is Air Mass per stroke

- Y Axis is Engine speed (RPM)

- Z axis (the field of cells) is ignition timing

As with any table within Maestro, the X and Y values can be modified to suit the users needs, however the Air Mass and RPM values as set on the base files should satisfy 99.99% of users and are not recommended to be modified.

Setting a Timing Curve

WARNING...DO NOT ADJUST ANY OF THE TIMING VALUES IN THE COLUMNS BELOW 1000MG/STROKE. Why? Daily driving around town from stoplight to stoplight the engine uses ignition timing fairly aggressively due to the lack of airmass (which is due to the lack of exhaust volume spinning the turbine) to power the vehicle. If you lower these values the car will feel sluggish at part throttle. If you increase these values the engine will knock. Only make changes to the last few columns of the tables. Once you get comfortable with tuning and are looking to move to more advanced manipulation (i.e bigger turbo, E85 blend timing, etc..) you may feel the need to increase or decrease values in some of the air mass columns in the 600-900 range. For larger framed/slow spooling turbos you may need to increase timing at low air mass to remove the off/on feeling. Winter gas blends often have less knock resistance that can often lead to excess low air mass/spool knock that one may seek to reduce without also reducing overall timing by adjusting the slider. Use your datalogs to make adjustments as needed. If you are consistently seeing knock in a few cylinders at a specific RPM range then adjust the timing down at that RPM and air mass area. It's best to make timing adjustments to both tables equally (or as equal as possible). If you are going to pull 1 degree of timing out at 6000 rpm in the 1299 air mass column then pull 0.375 from one and 0.75 from the other. If you feel like you need further reductions then pull more from the table that got the 0.375 reduction.

How much KR is too much KR?

This question comes up quite often. The answer is whatever you are most comfortable with. Some people don't want to see any KR. Some people say anything up to -3 degrees in 2 cylinders or less at the same time is ok. Most would agree that -4 or more is not a great idea and one should remedy that. Some cars seem more prone to KR, some have KR at specific RPM ranges that can't be removed with meth or even full E85. You might see one cylinder in particular that has more KR events than the others. Every motor is different. Use your own comfort level when setting timing.

~*~*~*~* Flame 'n' Bang ~*~*~*~*

You bang, bang, bang, bang, bang

Then flame, flame, flame

You bang, bang, bang, bang, bang

It's not my thing, so let it go

-Diggs

Unofficial changelog

Lol